Established in 1763, Fourstones Paper Mill has a wealth of knowledge that only experience can provide. That is why Fourstones excels at providing high quality paper.

Specialising in recycled paper grades, Fourstones operates 3 converting operations and 2 paper mills within the UK boasting 3 paper machines with an annual capacity of 32,000 tonnes.

Our expertise and passion for paper has achieved a strong reputation within the UK paper industry where we service many of the leading UK converting operations throughout the country with our consistent and high-quality paper.

“To be the industry leader in sustainable paper manufacturing, committed to ethical sourcing and environmental stewardship, creating a better world for all.”

“To provide hardworking manufacturers and distributors with consistently high-quality paper products, driven by our values honesty and integrity through ethical practices, environmental consciousness, and credible certifications. Our mission is to ensure a positive experience for end users, strengthening our relationships with distributing partners.”

The original paper mill was founded by William Charnley, a bookmaker from Newcastle Upon Tyne in 1763. The site began making handmade paper for the book industry.

The first paper making machine was installed in the 1840s and, although it has been modified and partially rebuilt over the years, it still remains installed in the paper mill museum to this day.

The name of the company was changed to South Tyne Paper Mill in the late 1860s.

The company finally became Fourstones Paper Mill Company Limited on its incorporation as a limited company in 1907.

Many paper grades were made over the years, from printing to cardboard and blackout paper. Between 1962 and 1975 this latest paper machine produced blotting paper, filter paper and absorbent grades.

In the 1970s a converting division, Warden Dressings, was established to produce underpads for incontinence.

A satellite converting operation was established in Haydon Bridge in 1989. The Warden Dressings division of the company remains the UK's largest manufacturer of cellulose wadding underpads.

Following former owner G.T. Mandl's death the company was sold February 2000 to current owners, Peter and Pauline Duxbury via an MBO.

Following acquisition in 2000, the paper machine within Fourstones underwent a rebuild to begin manufacturing AFH tissue grade paper.

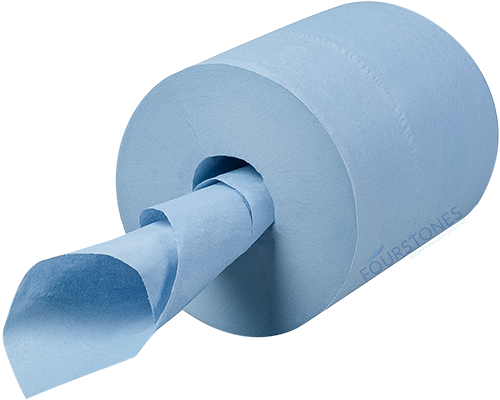

2003 saw the installation of Fourstones first AFH paper disposable range. The line focused on making Centrefeed & Toilet Tissue products for the AFH market.

Following the success of Fourstones new AFH paper disposable range a new warehouse was built next to the existing factory.

An additional AFH converting line was installed at Fourstones Paper Mill to accommodate growing demand. This line also introduced medical couch roll products to our range.

A large warehouse expansion was added in 2008 to accommodate Fourstones rapid growth.

To ensure the longevity of Fourstones, Sapphire Paper Mill (formerly Fettykil Mill) was acquired in 2009. The site which is 5 miles long lay dormant since 2006 but held exceptional potential.

2010 saw the completion of the PM2 rebuild at Sapphire Paper Mill. A monumental task was achieved in bringing life back to the previously closed Mill in Scotland.

2012 saw the installation of Sapphire Paper Mills first continuous AFH converting line specialising in Centrefeed products.

Building on the infrastructure at Sapphire Paper Mill, PM4 was converted from a heavy paper machine into a tissue paper machine, ensuring a complete internal supply of Recycled paper for Fourstones.

Company co-owner Peter Duxbury was awarded the prestigious Gold Paper Industry Award in 2015 for his contribution to the Paper Industry, both in technological advancement and preservation of the industry during a time of decline.

Purdi® was launched in 2018 as Fourstones first consumer brand. Using the tagline "The Elegant Alternative", Purdi® aims at feeling good and luxurious.

Following the success and improved run-ability of Fourstones new PM4 machine, the PM2 machine located at Sapphire Mill received a large upgrade to its wet end system with the addition of a new crescent former.

A natural progression for Fourstones Paper Mill was obtaining FSC® certification. This allowing the company to clearly demonstrate the ethical and environmental responsibility already practiced by Fourstones.

A new converting line was added to our converting facility at warden dressings, now known as Kattan disposables. Adding to our capacity, this new line exclusively manufactures high meterage centrefeed rolls.

A new converting line was installed at Sapphire Paper Mill. This line allows for bespoke & smaller batch products including single wrapped centrefeed.

2021 saw the introduction of HONEST®, Fourstones answer to excessive chemicals used in Paper production. This brand features no dyes, bleaches, H2O2 or deinking chemicals as well as 100% plastic free packaging.

2021 saw the addition of a brand new continuous PCMC converting line with Stax packaging equipment to Sapphire Paper Mill. This investment enabled Fourstones to bring all conventional and domestic toilet roll production in house.

Sapphire Paper Mill added new palletising & automation equipment in 2022 to further increase the capacity of existing converting equipment.

In 2022, Fourstones was shortlisted within the Large and Family business categories at the Fife Business Awards. It was an honour to be recognised within two prestigious categories.

Civils work began in 2023 for the announced PM6, a fourth paper machine located in Sapphire Paper Mill. This addition was Fourstones largest ever investment and is expected to nearly double the companies paper production.

The Confederation of Paper Industries awarded Fourstones with a highly commended certificate for Sustainable Innovation, recognising efforts made for genuine sustainable practices and the new HONEST® range.

Following an exclusive UK pilot, Fourstones achieved ISO 14064 in 2023. Demonstrating Fourstones ability to report its carbon footprint, whilst being verified by a credible auditing body.

The company was shortlisted for the Sustainable Manufacturer Award at the Manufacturer MX Awards 2023. Deemed the "Oscars of the UK Manufacturing Sector". Judges stated that we "Punch well above our weight".

At Fourstones, we’re dedicated to not just producing paper but also creating a sustainable future through our commitment to environmentally friendly practices – even before it was at the forefront of modern business.

We recycle over 45,000 tonnes of UK wastepaper annually, emphasising Fourstones key role within the UK circular Economy and preventing needless exports of waste paper and the associated carbon emissions of offshoring waste.

Our efforts haven’t stopped there; Fourstones environmental and sustainability efforts have been recognised by many credible industry bodies.

We listen to our customers’ needs and react to the ever-changing paper industry landscape.

We have developed a wide range of modern paper disposable products, perfect for all industries, from janitorial, facility management and industrial sectors, to medical, beauty and hospitality.

Our bespoke service, tailored to individual customer needs, is unrivalled in our industry. Our team of motivated, experienced and highly skilled employees continue to drive the business forward to meet your needs.

At the heart of Fourstones’ success lies our hands-on directors and deeply rooted family values of Honesty and Integrity.

We believe in leading from the front, hard work and collaboration. This gives us an in-depth understanding of our industries products, customer requirements and challenges, helping us deliver exceptional service and quality.

By always putting our customers and employees first whilst investing almost all of our profits back into the business, Fourstones has transformed into a leading UK manufacturer with over 180 staff across three locations.

If you would like to learn more about Fourstones Paper Mill, whether it’s our history or more of what we can offer, we encourage you to contact us today.

Established in 1763, the mill predates the formation of the United States of America. Underlining sustainability and modern investment, we utilise paper waste from a 25-mile radius to craft outstanding grades of specialist tissue paper. Our facility also includes two modern converting lines, alongside our central warehouse and distribution operation.

A satellite site of Fourstones Paper Mill, this location enhances our converting capacity by specialising in the manufacturing of wadding incontinence bed pads, centrefeed, bulk pack toilet tissue and facial tissue. Allowing us to meet diverse customer needs while maintaining the same commitment to quality and sustainability found at larger sites.

Dating back to the 1800’s, Sapphire Paper Mill was revitalised by Fourstones Paper Mill in 2010. The historic 30-acre site houses our largest paper machines, along with two exceptionally fast and high-quality continuous paper converting lines with further lines to manufacture bespoke offerings such as wrapped centrefeed. The modern transformation has enabled us to maintain our legacy while embracing innovation and efficiency.