Have you ever wondered how to measure centrefeed rolls? It may seem straightforward, however, taking accurate measurements of a centrefeed roll can prove tricky, and it’s easier to make mistakes than you might think.

There can be a variety of reasons to measure centrefeed, the main one being to check that a product meets the measurements stated on its label. With on-going shrinkflation across a range of industries, certain products may not live up to what they tell you. Unfortunately, it’s not unheard of to receive products that are significantly shorter than you expected, despite what the label might say. What’s more, some manufacturers may even increase the weight of cores, among other dirty tactics, to disguise the fact that their product isn’t up to spec. Knowing how to measure centrefeed means you can be confident that the product you have meets its specifications and hasn’t left you short changed.

If you already know your sheet dimensions and sheet count, why not skip ahead to our calculator to work out the square meterage of your paper!

1. Sheet Width

Method 1

The quickest and easiest way to measure the sheet width is to place the centrefeed roll on its side. Use a ruler or tape measure to measure the width of the roll to obtain the sheet width – easy!

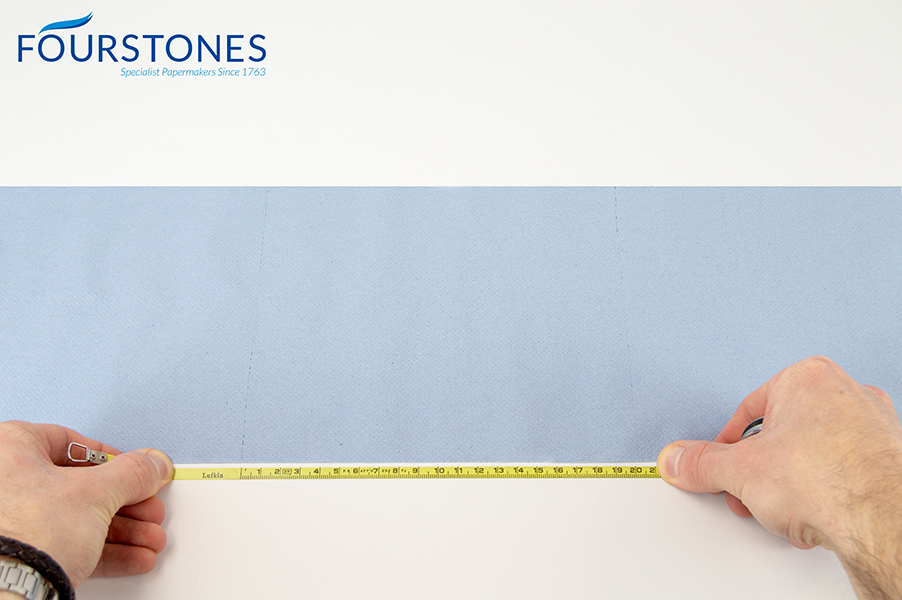

Method 2

Another way to measure sheet width is to tear off a single, undamaged sheet and lay it flat on a table, ensuring there are no folds or creases. Then, using an accurate tape measure or ruler, measure the width in millimetres along the edge of the sheet near the perforation tear to obtain the sheet width. Perforations can be angled so try not to measure directly along the tear!

2. Sheet Length

To obtain the sheet length, the process is very similar to measuring the sheet width. Firstly, remove 4 sheets from the roll and measure the length of each sheet, taking care to note each measurement. Afterwards, find the average sheet length by adding the 4 measurements together and dividing by 4. You will use the average sheet length later to find the total roll length.

You might wonder why it’s important to find an average sheet length instead of only measuring one sheet. This is to do with the fact that different centrefeed manufacturing equipment may have varying numbers of perforation blades to create each sheet. Depending on the machine, tiny discrepancies are possible, leading to different sheet sizes.

3. Sheet Count

Once you have recorded the sheet dimensions, it’s time to record how many sheets are in the roll. Make sure you don’t lose any sheets that you pulled off earlier, as these will contribute towards the total sheet count. We recommend the following straightforward methods.

Method 1

For the first method you will need a form of apparatus to place the roll on horizontally, such as our home-made roll dispenser below. This will allow you to easily unwind the roll as you count the sheets.

Once you have the roll secured, make sure you are free of distractions, there’s nothing worse than losing count! Carefully unwind the roll and count the sheets as you go. We recommend counting 20 sheets at a time to keep yourself right. Once you have counted 20 sheets, tear them off and place them on a table in a neat, folded pile. Repeat this process until you have unwound every sheet from the roll. Then, count your stacks of twenty sheets and multiply them by twenty, making sure to add on any sheets you tore off in Step 1 (Sheet Width) and Step 2 (Sheet Length) as well as any sheets at the end of the roll that don’t make up a stack of 20. Then, add the numbers together to get your total sheet count. In theory, this number should match what is displayed on the packaging if sheet count is mentioned.

Method 2

The second method is a little more hands-on and requires more space. The plus side is that no dispensers/holders are required. Although, a second pair of hands to hold the roll can be beneficial. This method can also be a little quicker.

Firstly, in an open space with a clean and unobstructed floor, begin to unwind the roll. You can unwind as many sheets as you have space for, however, it’s best stick to a number rounded to the nearest ten to make things easier. Once you have rolled out 30 sheets, for example, double count them to make sure you haven’t rolled out more or less than you intended. Then, roll out more paper so that it’s the same length as the first strip of paper. Repeat this process by layering the paper on top of each other in equal lengths until you have unwound the entire roll. Then, count how many layers you have and multiply that number by the number of sheets in the first row. Make sure to account for any sheets your tore off earlier and combine everything to get the total sheet count.

4. Roll Length

Once you have the average sheet length from Step 2 and the sheet count from Step 3, it is quick and easy to work out the total length of the roll in metres. Simply convert your sheet length and width to metres, then multiply by the total number of sheets you have counted. For example, if the sheet length is 200mm, dividing this by 1,000 would equal 0.2m. Then, if the sheet count is 500 sheets, the total length would be 0.2 x 500 which is 100 metres. Simply click the button below to use our handy calculator!

5. Square Meterage

All Fourstones products are proudly CHSA certified. The CHSA measure square meterage of a product, which can be conveniently worked out using the dimensions on our packaging, showing true transparency. What’s more, we don’t exploit tolerances, which is why you get the exact meterage and width that is stated on our labels. However, other brands might not make it so easy to work out the square meterage of a product.

Luckily, Steps 1-3 have given you all the information you need to calculate this accurately. Firstly, convert the average sheet length and the roll width to metres, then multiply the numbers together. E.g. 0.17 x 0.2 = 0.034m2 – this is the area of a single sheet. Next, multiply the sheet area by the sheet count – e.g. 0.034 x 500m = 17m2. Now you will have the square meterage for the entire roll. Don’t worry too much about the math, you can just use our handy calculator below.

Voilà! You now have the power to accurately determine the dimensions of a centrefeed roll. This means you can ensure that your customers won’t be let down by substandard dimensions and lower meterage, helping to build confidence and trust in your product.

Don’t forget to bookmark our calculator so it’s at hand whenever you need it!